The company's participation in the construction of China Coal Shaanxi's Dahaizhe coal mine put into operation a million tonnes of coal gangue away from the layer of grouting project in the "Shaanxi News Broadcast" report

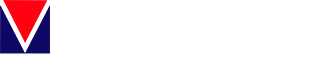

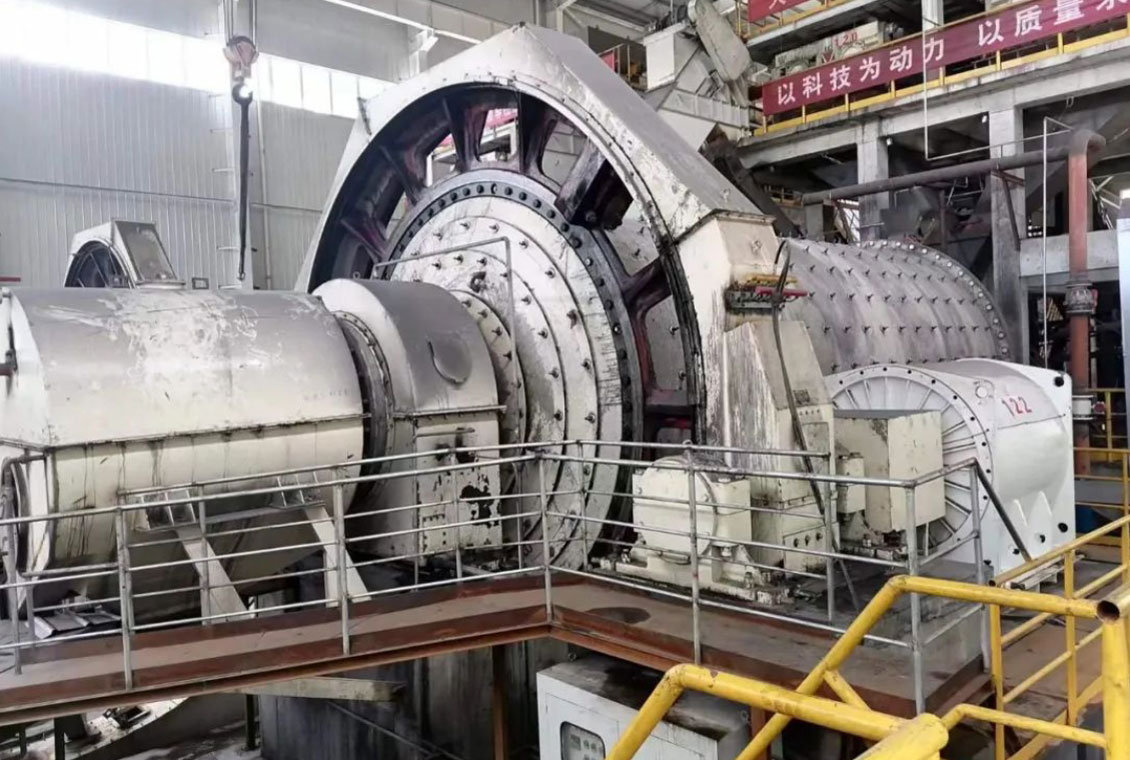

Recently, "Shaanxi News Broadcast" reported that China Coal Shaanxi Company's Dazhe coal mine put into operation a million-tonne coal gangue off-layer slurry injection project. The million-tonne coal gangue slurry injection project has recently been put into operation at Dazhe Coal Mine of China Coal Shaanxi Company, providing a new path for "producing coal without emitting carbon" and giving the traditional coal industry a new lease of life. At present, the maximum gangue handling capacity of the system can reach 4,000 tonnes per day, the future with the foreign gangue deployment complementary system is completed, the annual gangue handling can reach 1.5 million tonnes of stable. Shandong ShanKuang Machinery Co., Ltd. designed and manufactured the system of large ball mill and other products.

In the large sea is the coal mine million tonnes of coal gangue away from the layer of slurry filling project site, the project manager Wang Wei introduced: large ball mill running smoothly, the coal mining process generated in the gangue will be ground into a 2 mm powder, mixed with mine water made of gangue slurry, the use of grouting pumps and pipelines transported back to the underground, and greatly enhance the efficiency of the gangue processing.

ShanKuang has been committed to promoting circular economy solid waste treatment and reuse, green and low-carbon environmental protection in product research and development since 2003, to provide users with integrated solutions and equipment. The company has the earliest successful cases or exclusive cases in industries or fields such as biomass power generation, coke end recycling and reuse, gangue sintered bricks, fly ash aerated bricks and aerated panels, power plant slag reprocessing, steel slag reprocessing, electric power desulphurisation and environmental protection, desulphurisation gypsum reuse, etc., and has a high market share. Under the trend of energy transformation, green and low-carbon development, and the requirement of the state to strongly implement the construction of green mines, the company has invested in the development of coal gangue reuse mine filling field, and has designed and supplied complete sets of coal gangue filling system production line or part of the gangue slurry system preparation equipment, which is successfully applied in Shanxi Longquan Coal Mine, Hongqinghe Coal Mine, Shila Wusu Coal Mine, Tangjiahui Coal Mine, Caojiatan Coal Mine, Yingpantian Coal Mine, Baode Coal Mine, Tailianta Coal Mine, Wulanmulun Coal Mine, China Coal Dahaizhe Coal Mine, Bultai Coal Mine, Shanxi Yitang Zhanyuan Coal Mine and other gangue slurry filling projects.

Coal gangue off layer filling system can not only realise the resourceful use of coal, but also effectively eliminate environmental pollution, which is of great significance for promoting sustainable economic development, protecting the ecological environment and improving the efficiency of resource use. Next step, the company will continue to be based on scientific and technological innovation and high-quality development, market and user demand-oriented, and constantly improve and improve the coal gangue slurry filling system, digital, intelligent help coal mining enterprises green mining, for the early realization of the "dual-carbon" goal to contribute to the characteristic "Shanying "programme.

Related Products

Submitted successfully

We will contact you as soon as possible