Linear Vibrating Screen, with linear movement, has 24 kinds of specifications, which can be used in coal preparation, mineral processing, power generation, sugar-making, salt-making and other industries for processing mid-granule material by dry or wet sizing, dewatering, medium-drainage and desliming. Such screen has good features of advanced structure, low vibrating noise, long life and easy maintenance. The screen deck has structure of slot deck and woven wire mesh. The company can design for special requirement of users if punched screen deck or rubber deck is selected.

Contact Now

YA series vibrating screen, with circular movement, is mainly applied to metallurgical, mining, power plant, water conservancy project, building material, light industry and chemical industry, which is a high-effective sieving machine for sizing bulk material such as coal, ore and coke. This series of vibrating screen has 40 kinds of specifications, including heavy-duty screen for sizing large grain and light-duty for medium or small grain. The screen can be divided into single or double screen according to screening method.

Contact Now

This kind of screen is mainly used in coal, metallurgy, mine, power plant, construction material industry, water conservancy project, light industry and chemical industry.

Contact Now

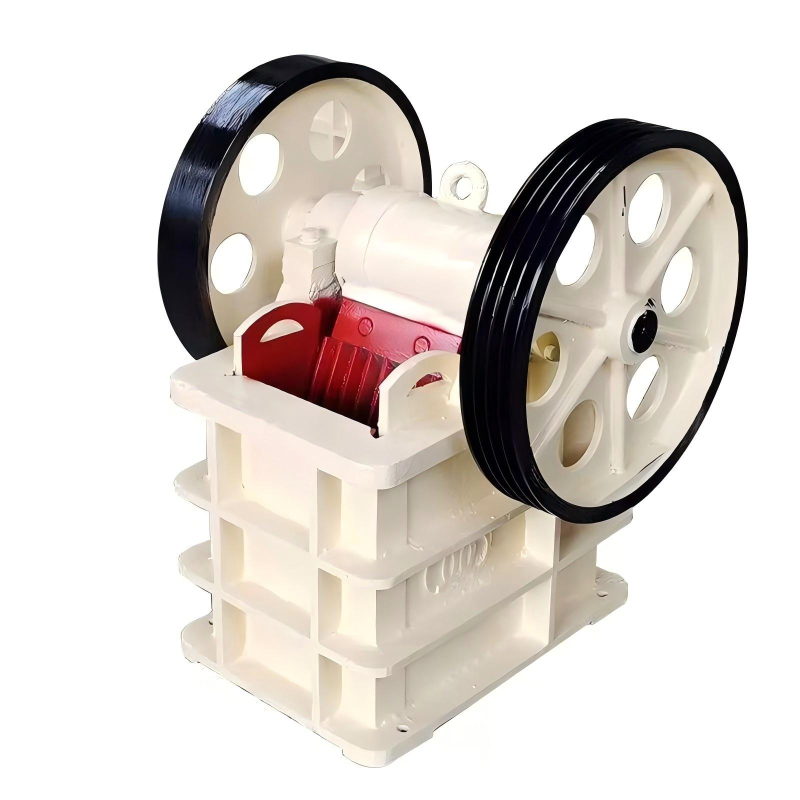

Jaw crusher is powered by electric motor, driving the eccentric shaft through the belt drive, so that the moving jaw makes reciprocating movement according to the predetermined track, so as to break the material into the crushing cavity composed of fixed jaw plate, movable jaw plate and side guard plate, and unload the finished material through the lower discharge port.

Contact Now

Four-roll crusher is a kind of medium and fine crushing products supporting metallurgical mining equipment. It breaks the required granular material by adjusting the gap of the upper and lower rollers.

Contact Now

Jaw crusher is suitable for the crushing of various materials, including but not limited to river pebble, granite, quartz, basalt, limestone, etc. It has a wide range of application scenarios, not only limited to the mining and building materials industry, but also including highway construction, bridge construction, water conservancy engineering and other fields.NameParameterRotor length X length(mm)Φ150×250Max.

Contact Now

Hydraulic jaw crusher is widely used in metallurgy, mining, building materials, chemical industry, coal and other industries, mainly used in primary crushing products. Through its own constant vibration, it can clip large stones into small pieces, which is suitable for crushing the rock after blasting to facilitate transportation and use. In addition, the hydraulic jaw crusher also has the function of overload protection.

Contact Now

hydraulic jaw crusher is suitable for coarse and medium crushing operations under harsh conditions with extremely hard and strong foreign matter in the material, especially for the treatment of steel slag. It adopts hydraulic support device and has functions of overload protection. The feeding particle size is not more than 425 mm. the product has the advantages of simple structure, reliable performance, convenient operation, safe use and so on. Main models: PEY400X600,PEY400X750,PEY500X750, PEY 600X900 and other models.

Contact Now

Jaw crusher can be divided into three types according to the inlet width: large, medium and small. The inlet width of large machines is more than 600mm, and the inlet width of medium machines is between 300-600mm, while the inlet width of small machines is less than 300mm. This classification enables the jaw crusher to adapt to application scenarios of different sizes and production requirements.NameParameterRotor length X length(mm) Φ500×750Max.

Contact Now

Hydraulic jaw crusher is suited for breaking coarse and middle sized material blended with extra hard foreign matters, especially suitable for steel slag breaking. This kind of crusher use hydraulic supporting device, have the overload protection function.

Contact Now

jaw crusher Stone Breaking Crusher Introduction:Stone Breaking Crusher is often used as primary and secondary crusher for mining, metallurgy, construction and some other industries.

Contact Now

The double roll crusher is a common crushing equipment used to break raw materials to the desired particle size. It usually consists of two or more parallel rotating rollers, and the gap between the rollers can be adjusted to control the broken particle size.

Contact Now

The working principle of the four-roll crusher is to use the high extrusion pressure and shear force generated by the relative rotation of the four high-strength wear-resistant alloy rollers to crush the material. The four-roller crusher integrates the primary and secondary crushing of materials, with compact structure, uniform particle size of broken materials, and less overcrushing ratio.

Contact Now

1. APPLICABLE SCOPEThe roller crusher is a common crushing equipment, widely used in mining, metallurgy, building materials, chemical and other industries. Its main function is to break the bulk material into smaller particles through the rotation of the double rollers to meet the needs of the subsequent process. The roller crusher has the characteristics of high efficiency crushing, uniform particle size, strong adaptability and simple maintenance.

Contact Now

1. Roller diameter: φ1600mm2. Rotor length: 2524mm3.Rotor quality: 13876kg4.Max.

Contact Now

The crusher is used for breaking all kind of ore or rock with material anti-pressure strength less than 2500kg/cm². It is widely used in the fields of building material, metallurgy, chemistry, coal mines etc.NameParameterRotor length X length(mm)Φ150×750Max.

Contact Now

Trolley Locomotive is a traction device for rail vehicle transportation, which use the traction motor as power to drive the wheels to rotate and with the help of friction between the wheels and the rail surface to enable the locomotive runs on the track. It is mainly used for underground transportation and long-distance transportation on the ground.

Contact Now

Double Tooth Roll Crusher has the advantages of small size, large crushing ratio, low noise, simple structure, convenient maintenance, high productivity, uniform particle size of broken materials, low crushing rate, convenient maintenance, sensitive overload protection, safe and reliable characteristics. This machine mainly uses special abrresistant roller to split the material to form the mechanism of high productivity. The double-tooth roller is driven by the universal coupling, and the roller gap can be adjusted by the gaskets.

Contact Now

Advantages of Electric Trolley Mining LocomotiveThe vector control transformer,AC frequency change electric motor and new locomotive cabinet designed and developed by yourself. The products has good sticking, good overload ability, good climbing, safety braking, big traction and easy to operate.Human oriented design, the operation table of driver cab has speed/odometer display and locomotive running signal lamp.Energy-saving, 25% energy saved compared to DC driving. The products can adapt mining working environment, accepted

Contact Now

PHZ type ring hammer crusher is suitable for crushing various ores, such as pyrite,phosphate ore, limonite, magnetite, limestone and cobblestone. Its compressive strength does not exceed 60MPa and the surface moisture does not exceed 15%. When the crushed particle size of pyrite ore and phosphate ore is less than 6mm, the surface moisture of the materials is less than 15%.The structural characteristics of the ring hammer crusher can adjust the output particle size. The product has particle size requirements after the material is crushed.

Contact Now

Heavy-duty Ring Hammer Crusher is a new product developed, suitable for power plant crushing coal crushing, large output, up to 200-2000T / H.1.Rotor diameter:1200(mm)2.Rotor length :4465(mm)3.Feed particle size:≤400(mm)4.Finishing particle size:≤25(mm)5.Capacity:1200(t/h)6.Power:630KW7.Overall size (LXWXH):7312×3460×1950mm8.Equipment wt.: excluding motor:42000Kg

Contact Now

Hammer crusher is a kind of equipment: single rotor and double rotor. It is a crusher that directly breaks a material of 600-1800 mm to 25 or 25 mm or less. Hammer crusher is suitable for cement, chemical, electric power, metallurgy and other industrial sectors broken medium hardness materials, such as limestone, slag, coke, coal and other materials in the crushing and fine crushing operation.NameParameterRotor length X length(mm) Φ600×400Max.

Contact Now

Main application of hammer crusher:Hammer crusher is used to crush all kinds of medium hard and weak abrasive materials. The compressive strength of the material is not more than 100MPa,and the moisture content is less than 15%. The crushed materials are coal, salt, chalk, gypsum, brick, limestone, etc.It can also be used to crush wood, paper or waste of asbestos cement with fiber structure, strong elasticity and toughness to recover asbestos fiber, etc. In addition, hammer crusher can not only be used in crushing production

Contact Now

Ring hammer crusher is one of crushing equipment, but also a kind of hammer crusher series technology advanced equipment, its role is to smash the stone into finished material. Heavy hammer crusher is an advanced high power, high crushing ratio, high productivity crusher, and broke through the previous crushing principle of crushing equipment, can be reasonably adjusted according to the nature of the material, in the output, power is better.NameParameterRotor length X length(mm)Φ800×800Max.

Contact Now