The mobile conveyor tripper car on the belt conveyor is a new type of mobile unloading equipment commonly used in the conveyor system and is used in conjunction with the belt conveyor. It is widely used in storage and transportation places in the metallurgy, mining, power, and grain industries; equipped with a good ventilation and dust removal system, can greatly reduce pollution. It is an upgrade product of the original conveyor tripper car product and adapts to the new requirements of various industries for environmental protection of the working environment.

Contact Now

The tooth roller crusher is suitable for crushing raw coal in coal mines or coal preparation plants, and can also be used for crushing other medium-low hard and brittle materials. The tooth roller spacing is adjusted hydraulically, and the tooth roller bearings are centrally lubricated. The tooth shape adopts optimal design, selective crushing with tensile and shearing forces, and with features of high efficiency and low consumption, and even granulation.

Contact Now

Adopt triangle belt driving between motor and reducer. The triangle belt will slip if load is too big, which can protect the motor. The connection between the swing roller part and reducer adopts universal spindle coupling, which not only make sure the swing roller have enough adjusting range but also protect the motor and reducer in case that damage due to overload. The roller part is the hardcore part of the crusher.

Contact Now

The comb roller has a hard rubber ring, which has a great effect to prevent the conveyor belt deviation and cleaning. It is specially used for the conveyor of sticky materials. Comcomb roll is applicable, including mining, wharf, coal, power plant, coking, export trade and other fields.

Contact Now

Linear Vibrating Screen, with linear movement, has 24 kinds of specifications, which can be used in coal preparation, mineral processing, power generation, sugar-making, salt-making and other industries for processing mid-granule material by dry or wet sizing, dewatering, medium-drainage and desliming. Such screen has good features of advanced structure, low vibrating noise, long life and easy maintenance. The screen deck has structure of slot deck and woven wire mesh. The company can design for special requirement of users if punched screen deck or rubber deck is selected.

Contact Now

The MQS series wet lattice ball mill is a device to grind ores and other materials of various hardness, which can be widely used as the main equipment for grinding operations in metal beneficiation, building materials, and chemical industry. It is called a lattice ball mill because the ore discharge grid is installed at the end of the ore discharge. Lattice ball mill consists of transmission part, rotary part, main bearing, feeding and discharging device, lubrication part and electric control part.

Contact Now

MQY series overflow ball mill is used to grind ores and other materials of various kinds of hardness. It can be widely used as the main equipment for grinding operations in industries such as metal beneficiation, building materials and chemical industry. It is called an overflow ball mill because the end of the ore discharge is based on the ore slurry level.

Contact Now

MB series rod mills are widely used in the primary grinding of artificial stone sand, metallurgical steel slag processing, mineral processing plants, power departments and chemical plants. The grinding body contained in the barrel of the rod mill is a steel rod, generally using a wet overflow type. The mill has the characteristics of uniform product size, less over-crushing phenomenon, higher grinding efficiency, and easy replacement of worn parts.

Contact Now

This kind of screen is mainly used in coal, metallurgy, mine, power plant, construction material industry, water conservancy project, light industry and chemical industry.

Contact Now

Double Tooth Roll Crusher has the advantages of small size, large crushing ratio, low noise, simple structure, convenient maintenance, high productivity, uniform particle size of broken materials, low crushing rate, convenient maintenance, sensitive overload protection, safe and reliable characteristics. This machine mainly uses special abrresistant roller to split the material to form the mechanism of high productivity. The double-tooth roller is driven by the universal coupling, and the roller gap can be adjusted by the gaskets.

Contact Now

The performance advantages of the double-tooth roller crusher include the use of long teeth, small roller diameter, spiral cloth teeth, multi-disc four-tooth structure, which can handle powder and granular materials, and has low water content requirements. The design is usually driven by two motors, and the kinetic energy is more powerful, saving 45% of the same capacity.

Contact Now

1. Application scopeThe crusher is suitable for breaking loose and fragile material with tensile strength not less than 100MPa, such as cold coke and coal lump.2. Main technical parameter2.1、Roller diameter: ¢500 mm2.2、Roller working length: 1500 mm2.3、Roller revolution: 64/67.8 r/min2.4、Max. feed size: 300mm2.5、Max.

Contact Now

1、 Application The crusher is suitable for breaking loose and fragile material with tensile strength not less than 100 MPa such as cold coke and coal lump.2、 Main technical data2.1、roller diameter ¢700 mm2.2、Roller working length 1500 mm2.3、roller revolution 75 r/min2.4、Max.

Contact Now

Tube belt conveyor is a new type belt conveyor developing from the basis of trough belt conveyor. The purpose of adopting the pipe belt conveyor is increasing the belt surround to the material which can reach the closed conveying to the material.

Contact Now

The Metal Packing Belt Conveyor is a standard product line that uses cotton canvas, nylon, polyester canvas, and steel cord conveyor belts as traction components for continuous conveying equipment. It can be widely applied in industries such as coal, metallurgy, electric power, mining, ports, chemicals, light industry, petroleum, and machinery to transport various bulk materials and components. The belt conveyor features high capacity, strong climbing ability, low operating costs, and ease of use and maintenance, making it suitable for the automation of transportation systems.

Contact Now

Industrial Conveyor Belt are universal series products, which are widely used for conveying all kinds of bulk material and finished product in the industries of coal, metallurgy, electrics, mining, port, chemical, petrol and machinery etc., adopting cotton cloth, nylon and wired core belt etc. as the traction element.Belt width500650800100012001400≥1600Max. lump100150200300350350400Notes: lump means the maximum linear size of the material

Contact Now

The conveyor transfer chutes is usually installed at the material collecting area of the belt conveyor, which plays the role of the material guiding centralizing to reduce the deviation of the belt and dust suppression and dust prevention. According to the different environment, it can be divided into a variety of structural types: general-purpose material conveyor transfer chutes, double-layer sealed material conveyor transfer chutes, fully enclosed material conveyor transfer chutes, non-powered dust-removing material conveyor transfer chutes, etc.

Contact Now

Mainly used for the sealing between the conveyor belt and the guide chute and the sealing between the buffer bed and guide chute.

Contact Now

Bend Pulley - A conveyor pulley used to redirect the belt and provide belt tension where bends occur in the conveyor system.The bend pulley is used for changing the direction of the belt. The bend pulley is usually installed at the tail part or the vertical take-up equipment part when the belt direction need to 180°bending.

Contact Now

Shankuang Company has established a professional manufacturing company specializing in carrier rollers for belt conveyors---- Shandong Shankuang Roller Manufacturing Co.,Ltd. The Company has an automated production line of carrier rollers and can produce various types of carrier rollers.

Contact Now

Conveyor Impact Bed is a kind of anti-flushing equipment specially designed for mining belt conveyor, with the characteristics of impact resistance, flame retardant and corrosion resistance. The Conveyor Impact Bed is mainly used to replace the traditional buffer roller. Through the high force of the material falls the impact force, greatly reducing the impact of the material falling on the conveyor belt, so as to improve the force of the drop point.

Contact Now

Characteristics of polyurethane scraper:1. Polyurethane scraper is made of polyurethane material, which has both the high strength of plastic and the high elasticity of rubber.2. Polyurethane scraper has ultra-high wear resistance, which is more than 5 times that of general rubber and plastic products.3. Polyurethane scraper hardness range is wide, 60A-95A hardness range. 4. Polyurethane scraper is resistant to oil and solvent, suitable for cleaning all kinds of materials. 5.

Contact Now

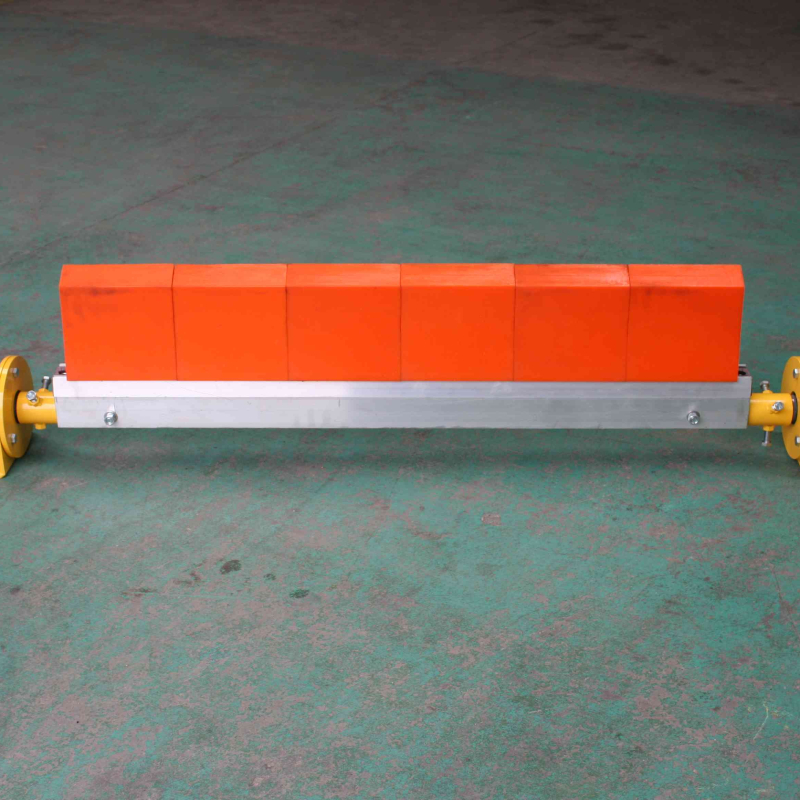

Impact Roller Idlers:Impact rollers are used as carrying rollers instead of normal steel rollers at a loading point. On steel roller there are rubber rings assembled, side by side, to absorb the weight and impact of material falling onto the belt. At the same time impact rollers reduce the shock and vibration through the steel structure.

Contact Now

The roller is an important part of the belt conveyor, many kinds, large quantity, can support the conveyor belt and material weight. It accounts for 35% of the total cost of a belt conveyor, generating more than 70% of the resistance, so the quality of the roller is particularly important.

Contact Now