MB series rod mills are widely used in the primary grinding of artificial stone sand, metallurgical steel slag processing, mineral processing plants, power departments and chemical plants. The grinding body contained in the barrel of the rod mill is a steel rod, generally using a wet overflow type. The mill has the characteristics of uniform product size, less over-crushing phenomenon, higher grinding efficiency, and easy replacement of worn parts.

Contact Now

The MQS series wet lattice ball mill is a device to grind ores and other materials of various hardness, which can be widely used as the main equipment for grinding operations in metal beneficiation, building materials, and chemical industry. It is called a lattice ball mill because the ore discharge grid is installed at the end of the ore discharge. Lattice ball mill consists of transmission part, rotary part, main bearing, feeding and discharging device, lubrication part and electric control part.

Contact Now

MQY series overflow ball mill is used to grind ores and other materials of various kinds of hardness. It can be widely used as the main equipment for grinding operations in industries such as metal beneficiation, building materials and chemical industry. It is called an overflow ball mill because the end of the ore discharge is based on the ore slurry level.

Contact Now

The MLTB series edge drive wet desulfurization ball mill is a special ball mill with limestone and gypsum wet flue gas desulfurization system developed by the company that absorbs the world's advanced technology. It is used for the preparation of limestone slurry, and its performance reaches the international advanced level. Compared with other types of ball mills, it has features of environmental protection, energy saving, simple maintenance, reliable operation, and high degree of automation.

Contact Now

Product description:MLT series compact center drive wet desulfurization ball mill is a special ball mill for limestone and gypsum wet flue gas desulfurization system developed by the company by introducing the world's advanced technology. It is used for the preparation of limestone slurry, and its performance reaches the international advanced level. Compared with other types of ball mills, it has features of environmental protection, energy saving, compact structure, light weight, easy installation and maintenance, reliable operation, and high degree of automation.

Contact Now

The crushing ratio is large, about 40, up to 150. The feeding size of the counterattack crusher is up to 2m3. The product particle size is less than 25mm, which can be directly put into the mill, and the product particle size of the finely broken counterattack crusher is less than 3mm. The selection of counterattack crusher can reduce the number of broken segments.1.Model:PF-1210ii2.Rotor length X length:ф1250×1050(mm)3.Max.

Contact Now

The crushing ratio is large, about 40, up to 150. The feeding size of the counterattack crusher is up to 2m3. The product particle size is less than 25mm, which can be directly put into the mill, and the product particle size of the finely broken counterattack crusher is less than 3mm. The selection of counterattack crusher can reduce the number of broken segments.1.Model:PF-1214ii2.Rotor length X length:ф1250×1400(mm)3.Max.

Contact Now

Strength Impact Crusher ratio is large, about 40, up to 150. The feeding size of the counterattack crusher is up to 2m3. The product particle size is less than 25mm, which can be directly put into the mill, and the product particle size of the finely broken counterattack crusher is less than 3mm. The selection of counterattack crusher can reduce the number of broken segments.1.Model:PF-1007ii2.Rotor length X length:ф1000×700(mm)3.Max.

Contact Now

Heavy-duty Ring Hammer Crusher is a new product developed, suitable for power plant crushing coal crushing, large output, up to 200-2000T / H.1.Rotor diameter:1200(mm)2.Rotor length :4465(mm)3.Feed particle size:≤400(mm)4.Finishing particle size:≤25(mm)5.Capacity:1200(t/h)6.Power:630KW7.Overall size (LXWXH):7312×3460×1950mm8.Equipment wt.: excluding motor:42000Kg

Contact Now

The conveyor transfer chutes is usually installed at the material collecting area of the belt conveyor, which plays the role of the material guiding centralizing to reduce the deviation of the belt and dust suppression and dust prevention. According to the different environment, it can be divided into a variety of structural types: general-purpose material conveyor transfer chutes, double-layer sealed material conveyor transfer chutes, fully enclosed material conveyor transfer chutes, non-powered dust-removing material conveyor transfer chutes, etc.

Contact Now

Tube belt conveyor is a new type belt conveyor developing from the basis of trough belt conveyor. The purpose of adopting the pipe belt conveyor is increasing the belt surround to the material which can reach the closed conveying to the material.

Contact Now

The mobile conveyor tripper car on the belt conveyor is a new type of mobile unloading equipment commonly used in the conveyor system and is used in conjunction with the belt conveyor. It is widely used in storage and transportation places in the metallurgy, mining, power, and grain industries; equipped with a good ventilation and dust removal system, can greatly reduce pollution. It is an upgrade product of the original conveyor tripper car product and adapts to the new requirements of various industries for environmental protection of the working environment.

Contact Now

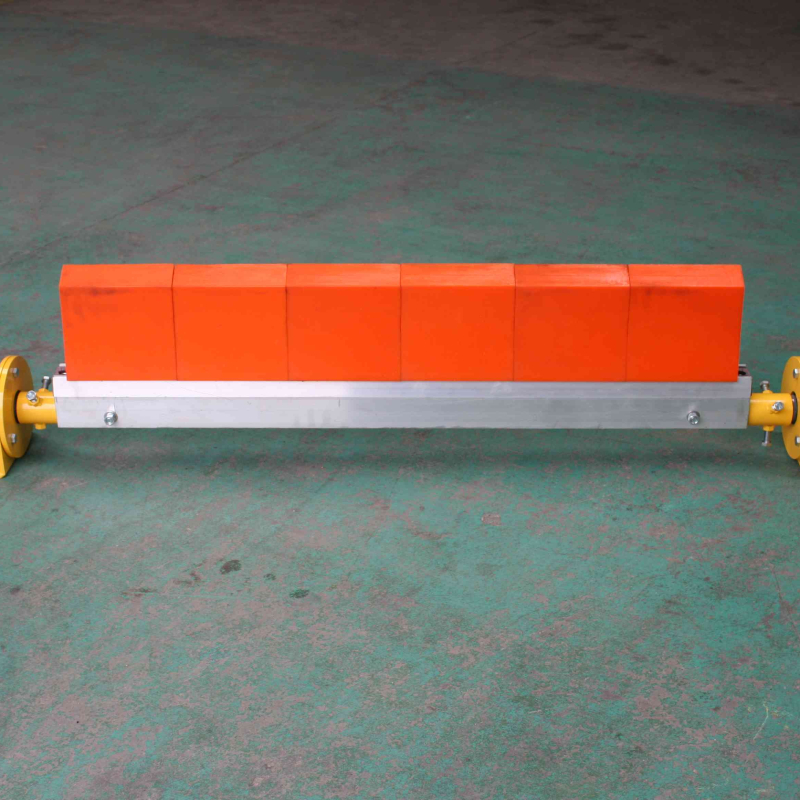

Mainly used for the sealing between the conveyor belt and the guide chute and the sealing between the buffer bed and guide chute.

Contact Now

General Belt Conveyor Shandong Shankuang researches and develops is a new style belt conveyor designed according to the mine and open pit coal mine digging and rock (waste) dumping process requirement. General Belt Conveyor is using for open pit digging and waste dumping area working surface, it is a kind of bulk material conveying equipment which is removable and configurable according to the operation requirement.

Contact Now

Heavy Duty Conveyor Belting is a general series of products, is the cotton canvas, nylon, polyester canvas and steel rope core conveyor belt as traction components of continuous conveying equipment, can be widely used in coal, metallurgy, electric power, mining, port, chemical, light industry, petroleum and machinery and other industries, conveying a variety of bulk materials and components.

Contact Now

The Metal Packing Belt Conveyor is a standard product line that uses cotton canvas, nylon, polyester canvas, and steel cord conveyor belts as traction components for continuous conveying equipment. It can be widely applied in industries such as coal, metallurgy, electric power, mining, ports, chemicals, light industry, petroleum, and machinery to transport various bulk materials and components. The belt conveyor features high capacity, strong climbing ability, low operating costs, and ease of use and maintenance, making it suitable for the automation of transportation systems.

Contact Now

Industrial Conveyor Belt are universal series products, which are widely used for conveying all kinds of bulk material and finished product in the industries of coal, metallurgy, electrics, mining, port, chemical, petrol and machinery etc., adopting cotton cloth, nylon and wired core belt etc. as the traction element.Belt width500650800100012001400≥1600Max. lump100150200300350350400Notes: lump means the maximum linear size of the material

Contact Now

Polyurethane pulleys are a type of pulley made using polyurethane material and are widely used in various industrial equipment.

Contact Now

Cold sticky pulley is a new type of pulley bonding method compared with the traditional pulley hot vulcanization casting method.Pulley cold bonding has been widely used in rubber surface coating of conveyor pulley in mining, port, power plant, metallurgy, cement, coal mine and other industries.

Contact Now

Head Drive Pulley, Return Pulley,Bend Pulley, Snub Pulley,Tensioning Pulley, Take up Pulley can be provided.We are designing and manufacturing pulleys, using materials of the highest quality in a production process employing advanced technology.

Contact Now

Characteristics of polyurethane scraper:1. Polyurethane scraper is made of polyurethane material, which has both the high strength of plastic and the high elasticity of rubber.2. Polyurethane scraper has ultra-high wear resistance, which is more than 5 times that of general rubber and plastic products.3. Polyurethane scraper hardness range is wide, 60A-95A hardness range. 4. Polyurethane scraper is resistant to oil and solvent, suitable for cleaning all kinds of materials. 5.

Contact Now

Drive/Head Pulley - A conveyor pulley used for the purpose of driving a conveyor belt. Typically mounted in external bearings and driven by an external drive source.Drive Drum is the main component of power transmission. The drum can be divided into single drum (the angle of the belt to the drum is 210°~ 230°),Double Drum (the angle of the belt to the drum is up to 350°) and multi-drum (used for high power)

Contact Now

A conveyor will always consist of at least two pulleys, head pulley and tail pulley, with additional pulleys used depending on the configuration. Standard-duty pulleys are usually adequate for simple applications, but mine-duty and engineered pulleys are also available where heavy-duty pulleys are required. Different kinds of conveyor pulleys ShanDongShanKkuang ® sells conveyor pulleys in all the following sub-categories:Head pulleysThe head pulley is located at the discharge point of the conveyor.

Contact Now

Advantages of Electric Trolley Mining LocomotiveThe vector control transformer,AC frequency change electric motor and new locomotive cabinet designed and developed by yourself. The products has good sticking, good overload ability, good climbing, safety braking, big traction and easy to operate.Human oriented design, the operation table of driver cab has speed/odometer display and locomotive running signal lamp.Energy-saving, 25% energy saved compared to DC driving. The products can adapt mining working environment, accepted

Contact Now