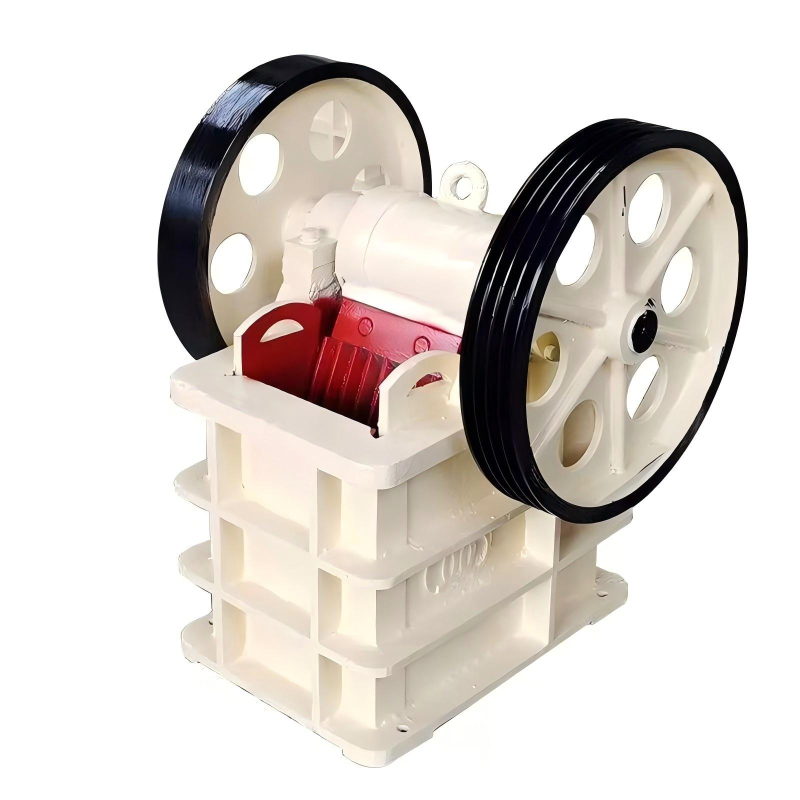

Jaw crusher, referred to as jaw breaker, consists of two jaw plates of dynamic Hubei and static jaw, which simulate the jaw movement of animals and complete the material crushing operation. It is widely used in mining, smelting, building materials, highway, railway, water conservancy and chemical industry, and the compressive strength of the crushed materials is 250 Mpa. Jaw crusher is mainly used as coarse and medium sher in mining, building materials, infrastructure and other departments.NameParameterRotor length X length(mm)Φ250×400Max.

Contact Now

Jaw crusher commonly known as jaw broken, also known as tiger mouth. A crusher that consists of two jaw plates, moving jaw and static jaw, which simulate the jaw movement of animals and complete the material crushing operation. Widely used in mine smelting, building materials, highway, railway, water conservancy and chemical industry in various ore and bulk material crushing.

Contact Now

The fine jaw crusher completes the material crushing operation by simulating the jaw movement of animals. It has the advantages of good processing effect, high crushing strength, large processing capacity, simple structure, strong work, reliable work and convenient operation and maintenance. It is one of the indispensable crushing equipment in the field of mine crushing.

Contact Now

Jaw crusher is powered by electric motor, driving the eccentric shaft through the belt drive, so that the moving jaw makes reciprocating movement according to the predetermined track, so as to break the material into the crushing cavity composed of fixed jaw plate, movable jaw plate and side guard plate, and unload the finished material through the lower discharge port.

Contact Now

Jaw crusher is suitable for the crushing of various materials, including but not limited to river pebble, granite, quartz, basalt, limestone, etc. It has a wide range of application scenarios, not only limited to the mining and building materials industry, but also including highway construction, bridge construction, water conservancy engineering and other fields.NameParameterRotor length X length(mm)Φ150×250Max.

Contact Now

Hydraulic jaw crusher is widely used in metallurgy, mining, building materials, chemical industry, coal and other industries, mainly used in primary crushing products. Through its own constant vibration, it can clip large stones into small pieces, which is suitable for crushing the rock after blasting to facilitate transportation and use. In addition, the hydraulic jaw crusher also has the function of overload protection.

Contact Now

Jaw crusher can be divided into three types according to the inlet width: large, medium and small. The inlet width of large machines is more than 600mm, and the inlet width of medium machines is between 300-600mm, while the inlet width of small machines is less than 300mm. This classification enables the jaw crusher to adapt to application scenarios of different sizes and production requirements.NameParameterRotor length X length(mm) Φ500×750Max.

Contact Now

Fine Crushing Jaw Crusher is suitable for crushing hard materials, such as limestone, iron ore, iron ore, phosphate ore, copper ore, silica ore, quartz ore, ceramics and solid materials of comparable hardness.NameParameterRotor length X length(mm) Φ300×1300Max.

Contact Now

Fine jaw crusher is mainly used for fine operation. The particle size of the feed is not greater than 120mm, and the compressive strength of the crushed material shall not exceed 250MPa.

Contact Now

Hydraulic jaw crusher is suited for breaking coarse and middle sized material blended with extra hard foreign matters, especially suitable for steel slag breaking. This kind of crusher use hydraulic supporting device, have the overload protection function.

Contact Now

hydraulic jaw crusher is suitable for coarse and medium crushing operations under harsh conditions with extremely hard and strong foreign matter in the material, especially for the treatment of steel slag. It adopts hydraulic support device and has functions of overload protection. The feeding particle size is not more than 425 mm. the product has the advantages of simple structure, reliable performance, convenient operation, safe use and so on. Main models: PEY400X600,PEY400X750,PEY500X750, PEY 600X900 and other models.

Contact Now

Fine jaw crusher is suitable for all kinds of ore and rock, widely used in mining, metallurgy, construction, chemical and other departments of crushing hard and hard materials, the most suitable for dressing plant ore and chemical plant raw materials of coarse, crushing, is one of the most commonly used crusher.NameParameterRotor length X length(mm) Φ250×750Max.

Contact Now

DetailsOur stone crusher machine, a type of jaw crusher is widely used in mining, railway construction, water conservancy project, metallurgy, chemical, building material industries. It is mainly used to crush rock and ore, whose compression strength is less than 320 Mpa. Jaw crusher, your preferred primary crusher, is used for coarse crushing and fine crushing.NameParameterRotor length X length(mm)Φ400×600Max.

Contact Now

jaw crusher Stone Breaking Crusher Introduction:Stone Breaking Crusher is often used as primary and secondary crusher for mining, metallurgy, construction and some other industries.

Contact Now

Fine crushing jaw crusher is a kind of efficient equipment used for crushing hard materials, especially suitable for the crushing of ore and rock, widely used in mining, metallurgy, construction, chemical industry and other fields. It can deal with all kinds of hardness and medium hardness materials, including but not limited to limestone, iron ore, steel slag, phosphate ore, copper ore, silicon ore, quartz stone, etc., and is suitable for secondary medium crushing operations.NameParameterRotor length X length(mm) Φ250×1500Max.

Contact Now

The crusher is used for breaking all kind of ore or rock with material anti-pressure strength less than 2500kg/cm². It is widely used in the fields of building material, metallurgy, chemistry, coal mines etc.NameParameterRotor length X length(mm)Φ150×750Max.

Contact Now

The double roll crusher is a common crushing equipment used to break raw materials to the desired particle size. It usually consists of two or more parallel rotating rollers, and the gap between the rollers can be adjusted to control the broken particle size.

Contact Now

Adopt triangle belt driving between motor and reducer. The triangle belt will slip if load is too big, which can protect the motor. The connection between the swing roller part and reducer adopts universal spindle coupling, which not only make sure the swing roller have enough adjusting range but also protect the motor and reducer in case that damage due to overload. The roller part is the hardcore part of the crusher.

Contact Now

Impact Crusher machinery has the characteristics of good grain type, simple structure, durable, suitable for all kinds of coarse, medium and fine materials, such as side length not more than 500mm, compressive strength not more than 350MPa, such as granite, limestone, concrete, etc.NameParameterRotor length X length(mm)Φ500×400Max.

Contact Now

Four-roll crusher is a kind of medium and fine crushing products supporting metallurgical mining equipment. It breaks the required granular material by adjusting the gap of the upper and lower rollers.

Contact Now

It is a medium and fine crusher with a simple, compact and light construction. Such crusher has large adjustment range of grain size and cutting device for repairing wear roll, which can easily adapt to humid material and is good at discharging material smoothly.

Contact Now

This Impact Crusher 1000×1000m is a new type of crusher designed by introducing and absorbing the latest technology at home and abroad.It is suitable for crushing materials with compressive strength ≤350 MPa and is widely used in highway, railroad, high strength dam and other projects.It is widely used in highway, railway, high-strength dams and other projects to crush rocks and construction waste (such as bricks, concrete blocks, etc.).NameParameterRotor length X length(mm)Φ1000×1000Max.

Contact Now

Strength Impact Crusher ratio is large, about 40, up to 150. The feeding size of the counterattack crusher is up to 2m3. The product particle size is less than 25mm, which can be directly put into the mill, and the product particle size of the finely broken counterattack crusher is less than 3mm. The selection of counterattack crusher can reduce the number of broken segments.1.Model:PF-1007ii2.Rotor length X length:ф1000×700(mm)3.Max.

Contact Now

The crushing ratio is large, about 40, up to 150. The feeding size of the counterattack crusher is up to 2m3. The product particle size is less than 25mm, which can be directly put into the mill, and the product particle size of the finely broken counterattack crusher is less than 3mm. The selection of counterattack crusher can reduce the number of broken segments.1.Model:PF-1210ii2.Rotor length X length:ф1250×1050(mm)3.Max.

Contact Now