The MLTB series edge drive wet desulfurization ball mill is a special ball mill with limestone and gypsum wet flue gas desulfurization system developed by the company that absorbs the world's advanced technology. It is used for the preparation of limestone slurry, and its performance reaches the international advanced level. Compared with other types of ball mills, it has features of environmental protection, energy saving, simple maintenance, reliable operation, and high degree of automation.

Contact Now

Product description:MLT series compact center drive wet desulfurization ball mill is a special ball mill for limestone and gypsum wet flue gas desulfurization system developed by the company by introducing the world's advanced technology. It is used for the preparation of limestone slurry, and its performance reaches the international advanced level. Compared with other types of ball mills, it has features of environmental protection, energy saving, compact structure, light weight, easy installation and maintenance, reliable operation, and high degree of automation.

Contact Now

The MQS series wet lattice ball mill is a device to grind ores and other materials of various hardness, which can be widely used as the main equipment for grinding operations in metal beneficiation, building materials, and chemical industry. It is called a lattice ball mill because the ore discharge grid is installed at the end of the ore discharge. Lattice ball mill consists of transmission part, rotary part, main bearing, feeding and discharging device, lubrication part and electric control part.

Contact Now

MQY series overflow ball mill is used to grind ores and other materials of various kinds of hardness. It can be widely used as the main equipment for grinding operations in industries such as metal beneficiation, building materials and chemical industry. It is called an overflow ball mill because the end of the ore discharge is based on the ore slurry level.

Contact Now

Advantages of Electric Trolley Mining LocomotiveThe vector control transformer,AC frequency change electric motor and new locomotive cabinet designed and developed by yourself. The products has good sticking, good overload ability, good climbing, safety braking, big traction and easy to operate.Human oriented design, the operation table of driver cab has speed/odometer display and locomotive running signal lamp.Energy-saving, 25% energy saved compared to DC driving. The products can adapt mining working environment, accepted

Contact Now

The company, as a vice chairman unit of breaking and grinding sub-association of China Heavy Machinery Industry Association, has been closely combining with industry trends and requirements of the users, actively. studying new technologies and new processes in the world, constantly optimizing product structure and improving product property and processing capabilities. At present, breaking series of products have moved towards automation, whole set and large-scale, energy-economical and environmental orientation,with property index of most products

Contact Now

Impact Crusher have the advantages of simple structure,high brcaking ratio,low energy consumption、the discharged granules are of high even degree and seldom over smash phenomenon,maintain convenient、granule degree be of large adjustment scope and can be broken selected.They are used in cement,fireproof materials in transportation(railway,highway and bridges)、coal、metallurgy and power construction ctc.industries for breaking medium and fine materials,such as rock、limestone、clinker、slag、coke,coal etc.Type PF-Ⅱ,PF-Ⅲ impact crushers have the following characteristics:breaking of hard rocks,wear-re

Contact Now

Technical Specifications of PF 1210 lmpact CrusherThe rotor diameter is 1250mm, the rotor length is 1050 mm, the maximum feeding size is 350mm, the production capacity is 70-120t/h, the rotor speed is 508r / min, the motor power is 110KW, and the overall dimension (length x width x height) of PF 1210 impact crusher is 2945x3028x2809mm.An impact crusher is a crushing machine that uses impact energy to crush materials. The rotor rotates high speed when the machine is working, driven by the motor.

Contact Now

The performance advantages of the double-tooth roller crusher include the use of long teeth, small roller diameter, spiral cloth teeth, multi-disc four-tooth structure, which can handle powder and granular materials, and has low water content requirements. The design is usually driven by two motors, and the kinetic energy is more powerful, saving 45% of the same capacity.

Contact Now

1.Model:PF-13152.Rotor length X length:ф1300×1500(mm)3.Max. feeding size:150~350(mm)4.Capacity:100~250(t/h)5.Power:180~315KW6.Overall size (LXWXH):2230×3515×1515mm7.Equipment wt.: excluding motor:23000KgNotes: The capacity listed in the table is obtained under following condition:1. Material to be crushed is ore.2.The anti-pressure strength of material of ore within 200MPa.3.Surface water content within 2%.4.Bulk density is 1.6t/m3.5.Feed material along full length of rotor evenly and continuously.An impact crusher is a crushing machine that uses impact energy to crush materials.

Contact Now

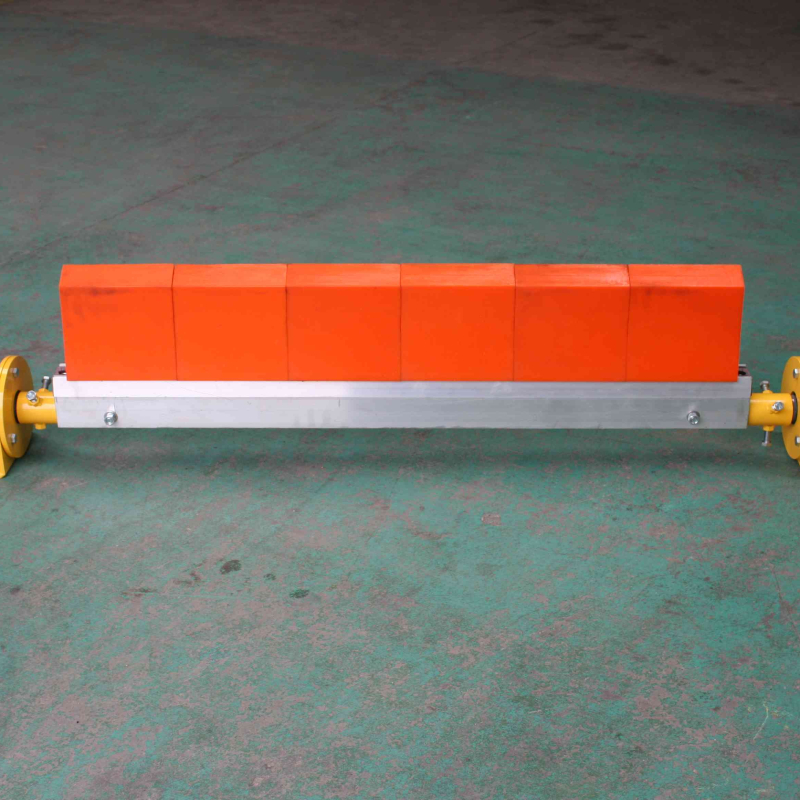

Spiral roller is an important part of belt conveyor. Its product structure design and function characteristics make it perform well in the environment of conveying sticky wet materials, with the characteristics of non-stick roller, strong self-cleaning force and non-stick belt. The spiral roller is easy to install, can provide smooth transmission, and has the advantages of low noise, low energy consumption and prolong the service life of the tape.

Contact Now

Tapered Roller is divided into cone up heart roll, cone down heart roll group, widely used in steel mills, power plants, wharf, coal mine and other transportation industries, it has wear resistance, impact resistance, aging, no noise, antistatic, self-lubrication does not tear the conveyor belt, reduce resistance suitable for long distance transmission to reduce energy consumption.NO.NumberNameWeight Size1DTⅡ03C1211.1Tapered Roller5.6¢89×¢133-340-4G2042DTⅡ03C1222.1Tapered Roller5.6¢89×¢133-340-4G2053DTⅡ04C1223.1Tapered Roller7.0¢108×¢159-4

Contact Now

PCFK1413 reversible impact crusher is widely used in highways, coal, railroads, airports and other fields that require high shape of stone materials. The equipment has the following features and performance:1. Large crushing ratio and high crushing efficiency: through high-speed impact and repeated crushing, PCK1413 Reversible Impact Crusher is able to quickly crush large materials to the required size, and is suitable for all kinds of materials with compressive strength not exceeding 360 MPa.2.

Contact Now

The working principle of the four-roll crusher is to use the high extrusion pressure and shear force generated by the relative rotation of the four high-strength wear-resistant alloy rollers to crush the material. The four-roller crusher integrates the primary and secondary crushing of materials, with compact structure, uniform particle size of broken materials, and less overcrushing ratio.

Contact Now

Ring hammer crusher is one of crushing equipment, but also a kind of hammer crusher series technology advanced equipment, its role is to smash the stone into finished material. Heavy hammer crusher is an advanced high power, high crushing ratio, high productivity crusher, and broke through the previous crushing principle of crushing equipment, can be reasonably adjusted according to the nature of the material, in the output, power is better.NameParameterRotor length X length(mm)Φ800×800Max.

Contact Now

Characteristics of polyurethane scraper:1. Polyurethane scraper is made of polyurethane material, which has both the high strength of plastic and the high elasticity of rubber.2. Polyurethane scraper has ultra-high wear resistance, which is more than 5 times that of general rubber and plastic products.3. Polyurethane scraper hardness range is wide, 60A-95A hardness range. 4. Polyurethane scraper is resistant to oil and solvent, suitable for cleaning all kinds of materials. 5.

Contact Now

Double tooth roller crusher, also known as 2 PGC of roller crusher, is mainly used in ore operations, by transmission device, frame part, crushing roller, mechanical spring device, linkage mechanism, etc., and the wear-resistant tooth roller high-speed rotation of material split, instant hard broken, not broken, formed the mechanism of high productivity, operation and maintenance is more convenient.

Contact Now

This Impact Crusher 1000×1000m is a new type of crusher designed by introducing and absorbing the latest technology at home and abroad.It is suitable for crushing materials with compressive strength ≤350 MPa and is widely used in highway, railroad, high strength dam and other projects.It is widely used in highway, railway, high-strength dams and other projects to crush rocks and construction waste (such as bricks, concrete blocks, etc.).NameParameterRotor length X length(mm)Φ1000×1000Max.

Contact Now

The coal block is crushed initially after entering the crusher under the impact of the high-speed rotating ring hammer, and then crushed again when rushed to the crushing plate and sieve plate at high speed. Meanwhile, the coal blocks also collide with each other. The impacted coal is sheared and crushed between the ring hammer and the crushing plate and sieve plate, flowing from top to bottom, continuously crushed, and discharged from the sieve hole after reaching the required particle size.

Contact Now

Double Tooth Roll Crusher has the advantages of small size, large crushing ratio, low noise, simple structure, convenient maintenance, high productivity, uniform particle size of broken materials, low crushing rate, convenient maintenance, sensitive overload protection, safe and reliable characteristics. This machine mainly uses special abrresistant roller to split the material to form the mechanism of high productivity. The double-tooth roller is driven by the universal coupling, and the roller gap can be adjusted by the gaskets.

Contact Now

The advantages of PF1210 impact crusher are high crushing efficiency, low power consumption, uniform product size, can reduce the number of crushing stages, simple structure, large production capacity, impact crusher plate hammer and liner plate, etc. using high wear-resistant materials, simplify the production process, suitable for large and medium scale crushing production. It is applied to the crushing of large materials in metallurgy, building materials, mining, highway, mineral processing and other industries.NameParameterRotor length X length(mm)Φ1250×1000Max.

Contact Now

The fine jaw crusher completes the material crushing operation by simulating the jaw movement of animals. It has the advantages of good processing effect, high crushing strength, large processing capacity, simple structure, strong work, reliable work and convenient operation and maintenance. It is one of the indispensable crushing equipment in the field of mine crushing.

Contact Now

YA series vibrating screen, with circular movement, is mainly applied to metallurgical, mining, power plant, water conservancy project, building material, light industry and chemical industry, which is a high-effective sieving machine for sizing bulk material such as coal, ore and coke. This series of vibrating screen has 40 kinds of specifications, including heavy-duty screen for sizing large grain and light-duty for medium or small grain. The screen can be divided into single or double screen according to screening method.

Contact Now

The main shaft of reversible counterattack hammer crusher is made of high quality alloy forged steel, and the material and heat treatment technology have been very mature in the application of large surface shaft parts for decades. The hammer heads are combined, thus saving a lot of wear-resistant alloy materials and reducing production costs.

Contact Now